Our quality system is mastered in order to to maintain our quality commitment and certifications at the highest level : ISO IATF 16949, EN 9100, EN 9001:2015 and ISO 14001 (in progress)

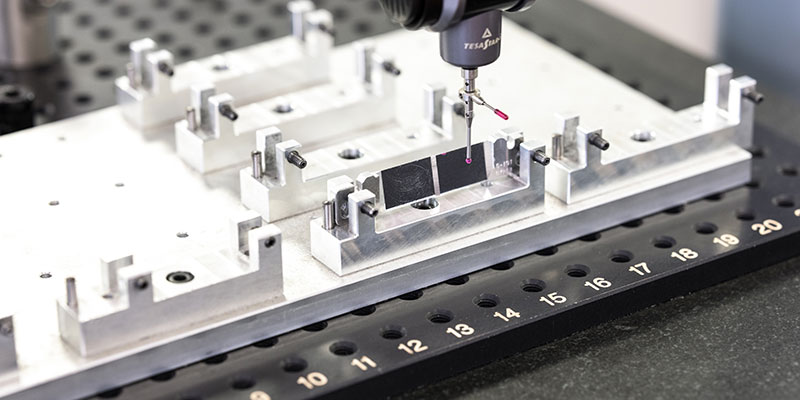

Our measurement system is based on the equipment of our metrology laboratory :

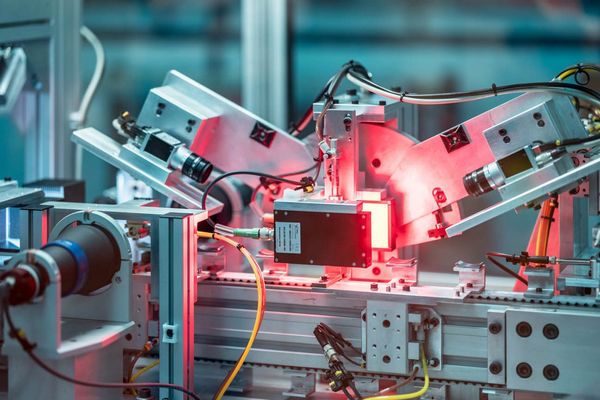

To meet our clients’ requirements, we are equipped with automatic inspection machines that combine various technologies :

The PDCA cycle is a tool that enables solid and sustainable results in terms of improving the efficiency of management systems. As part of a continuous improvement approach, we will always seek to improve our systems instead of sticking to the attained results, even if they are satisfactory.

The first question of the 5-Why method provides the immediate actions to be taken to prevent the incident from happening again. The 5-Why iteration reveals the root cause of the problem, for instance : the maintenance procedure was not available and of the employee in charge of maintenance for this machine was absent, so no one could perform the necessary actions and properly monitor the machine, which resulted in a small oil leak. Finding the root cause of the problem ensures a higher performance!

This tool is based on questions too : Who, What, Where, When, How, Why ? These different interrogative pronouns are used to specify the subject being treated. When properly defined, solving the problem is easier or the target is followed more clearly.

The main goal of QRQC is to have a clearly defined methodology to react as quickly as possible to a problem. QRQC allows to manage production issues as soon as they happen, by involving the concerned persons who have detected and described the problem. It is a method based on the reality of the field that avoids wasting time in meetings.

In order to guarantee the traceability of our products, we have invested in state-of-the-art laser marking technology, capable of producing both DATAMATRIX and QR codes. Additionally, we offer surface texturing solutions to further enhance the identification and tracking of our products.

Our workshop is equipped with an automated storage cabinet for managing our cutting tools as well as an automatic cabinet for managing our spare parts.