Our 45 years of expertise in machining of drawn profile or rolled steel profile enable us to manufacture precision components for firearms such as:

We can machine steels such as 42CrMo4 +QT and stainless steels such as AISI 316L and X19NiCrMo4.

The continuity of material fibers and homogeneity of hot and cold formed steel profiles enable high fatigue resistance. The combination of materials and heat treatment processes used on the profiles, combined with dedicated machining methods, enable resistance of up to 1,200 MPa / 64 HRC and increased m0geometrical precision.

Our R&D department defines the optimal manufacturing process by developing the profile to be machined, the clamping and machining systems to ensure product quality (calculation of deformations during machining, anticipation of distortions after heat treatment, etc.).

We combine additional operations with machining to improve the quality of our products.

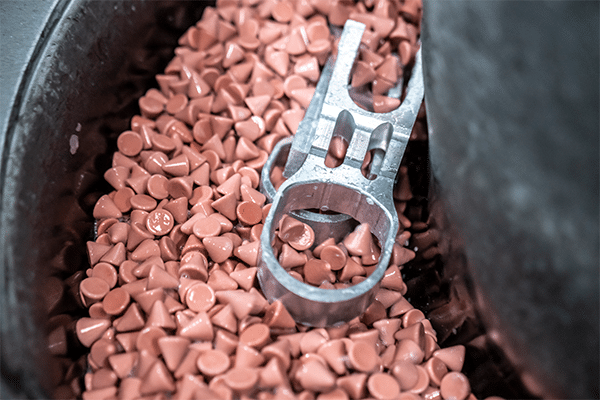

We perform in-house finishing by shot peening or mass finishing for deburring, polishing, and improving surface criteria (roughness and bearing capacity).

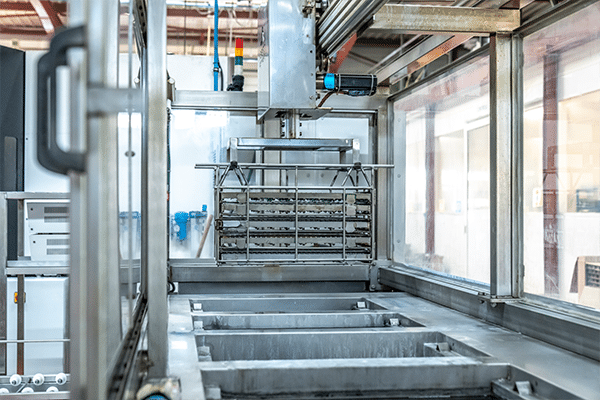

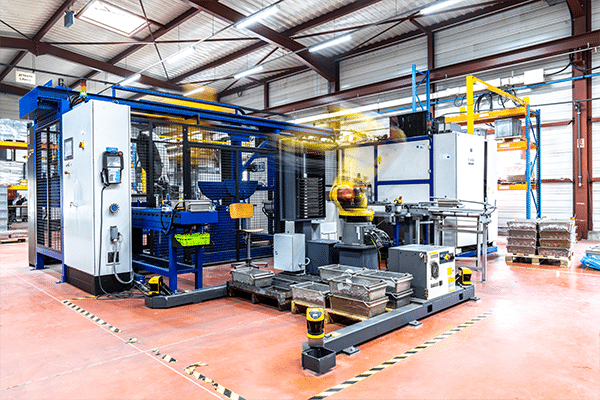

The cleanliness requirements of our products are guaranteed by a multi-tank, ultrasonic, detergent washing line and a robotized, modified alcohol washing line.

The cleanliness requirements of our products are guaranteed by a robotized, modified alcohol washing line.

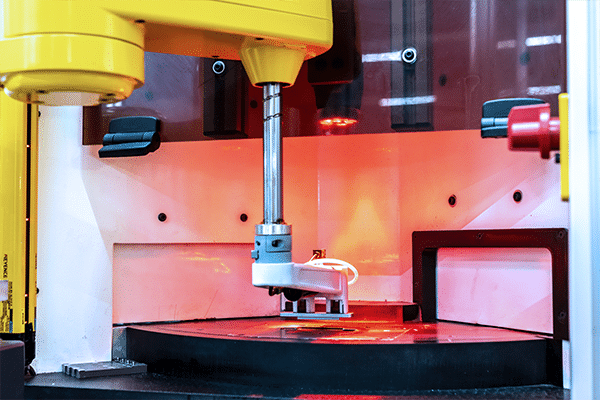

Unit traceability is carried out using automatic laser marking machines such as QR CODE or DATAMATRIX.